Full-cycle solutions for comprehensive projects, from engineering to after-sales service.

Developing projects from the Consulting and Engineering phase, being manufacturers of a wide variety of equipment, and integrating third-party equipment required to complement our own allows us to offer complete solutions, designed together with the customer and fully aligned with their requirements. If we add the Electrical Engineering and Programming of these projects, the Installation and Commissioning of the facilities with our own personnel, and an efficient After-sales Service, we are able to provide our customers with full-cycle solutions throughout the entire service life of the project. Different combinations of our equipment enable us to offer the following Systems to deliver specific solutions for each need.

Solution 1 / 10

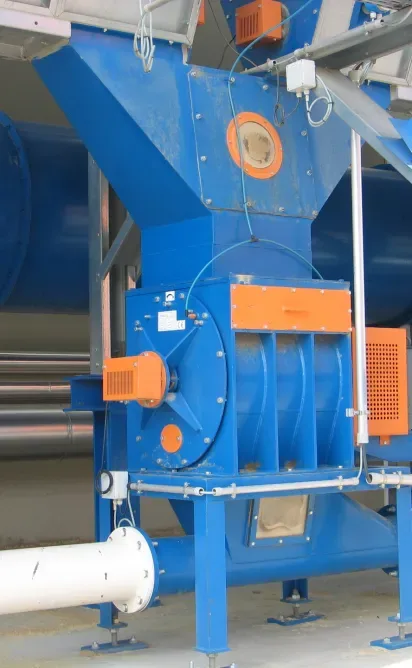

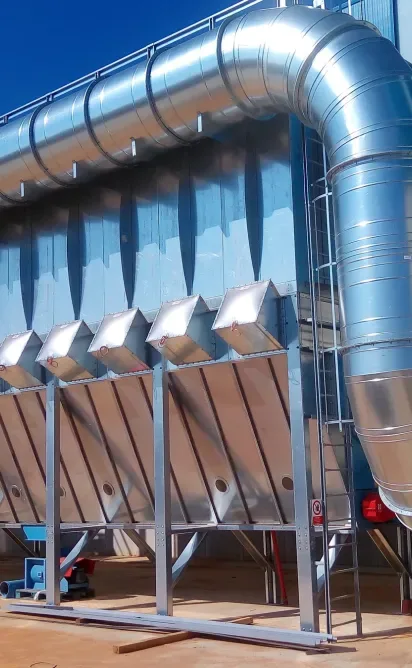

Extraction and filtration systems

Made up of a combination of ducting, filter units, centrifugal fans, cyclones, rotary valves and the corresponding safety systems to comply with ATEX regulations.

Solution 2 / 10

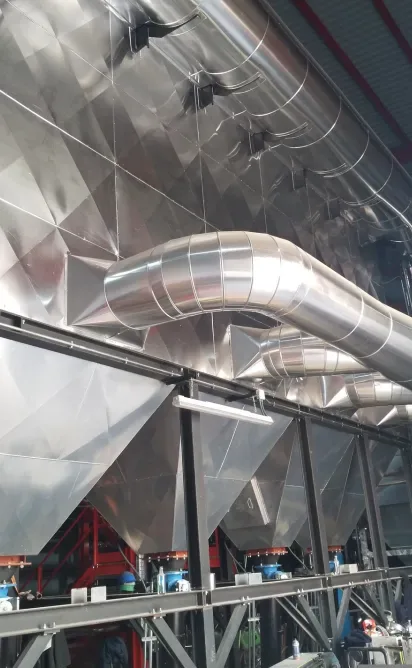

Solids conveying, storage, extraction and dosing systems

These systems combine receiving and storage silos with conveying and dosing equipment such as Redler-type chain conveyors, belt conveyors and screw conveyors. The breadth of our equipment range allows us to provide solutions for a very wide variety of needs.

Solution 3 / 10

Pneumatic conveying

Suitable for conveying solids with small particle size. Depending on the characteristics of the material to be conveyed, the quantity and the conveying distance, we define the most appropriate type of pneumatic conveying system—high or low pressure.

Solution 4 / 10

High-vacuum cleaning systems

They allow material extracted and collected mainly in filter units and cyclones to be discharged into containers. The system enables uniform filling (via screw conveyors) of one or two containers, keeping them covered during filling. Its automation includes: fill-level control, automatic container changeover and full integration with the extraction system.

Solution 6 / 10

Boiler flue-gas filtration

Building on the experience gained in the design and manufacture of pneumatic conveying systems, we adapt them to the cleaning of production facilities where dust accumulations may occur. With a ducting network and connections distributed throughout the plant, cleaning nozzles and brushes with quick couplings, a blower operating under vacuum, and a filtration unit, we enable effective cleaning of the defined areas.

Solution 7 / 10

Spark detection and extinguishing systems

Oñaz is the exclusive distributor in Spain for GreConSpark Detection and Extinguishing Systems. GreCon is a world leader in these types of systems and in measurement technologies. Safety is an essential factor in our installations, and working with leading partners is key to our strategy of continuous development. Spark detection and extinguishing systems can be used in a wide variety of industries and processes, including: filtration systems, the woodworking industry, recycling plants, the metal industry, etc.

Solution 8 / 10

Briquette manufacturing

Following the strategy of collaborating with leading companies in their sectors, Oñaz is the exclusive distributor in Spain for Briquetting Systems from C.F. Nielsen, a world leader in the manufacture of both mechanical and extrusion briquette presses. Among the most popular solutions are briquette production lines for domestic use, as well as briquette production for industrial boilers and agriculture.

Solution 10 / 10

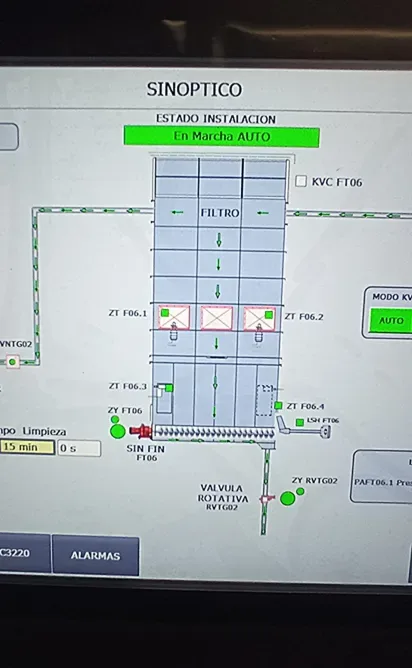

Electrical automation

At Oñaz we have developed a complete Electrical Department that enables us to design, manufacture and install the electrical equipment included in our solutions. Safety, energy efficiency, remote support, the use of leading international brands, and environments that facilitate any kind of intervention throughout the service life of the installations are the core principles of our developments.

Solution 9 / 10

Safety elements

Depending on the characterization of the extracted dust, its concentration, and the Extraction and Filtration System used, we define and incorporate the most suitable prevention (Spark Detection and Extinguishing Systems) and protection elements (isolation valves, rotary isolation valves, chemical isolation systems and explosion vents).