Lorem ipsum dolor sit amet, consectetur adipiscing elit. Proin hendrerit ligula a lectus malesuada tincidunt.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec suscipit, lectus convallis accumsan tempus, urna nulla consequat sapien, posuere convallis enim augue ut lorem. Proin luctus nisi id justo lacinia viverra ac vitae nulla. Integer eget semper dolor. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Etiam gravida risus elit, ac consectetur diam tristique eget. Fusce rhoncus molestie lorem, quis tempor elit rhoncus et. Aenean turpis neque, placerat vitae lacinia imperdiet, ornare vel lorem.

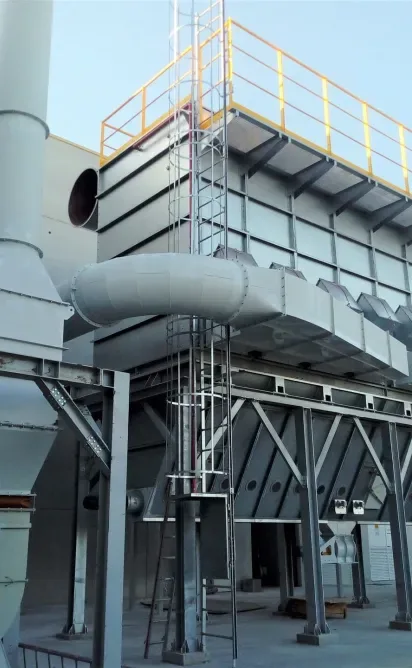

Equipment 1/10

Filter units.

We manufacture a wide range of Filter Units, enabling us to provide filtration solutions for a broad set of industries.

Equipment 2/10

Filter cells.

Designed to operate with low airflows in localized extraction points or in a small group of them, they use cartridges as the filtering element. Oñaz manufactures two series of filter cells: the VF series with an integrated extractor, and the F series without an extractor. The ability to select different cartridge diameters, their length and quantity, the discharge method (container, rotary valve, etc.), and the option to include an electrical cabinet for control, allows us to adapt to a wide range of situations, customizing them for each project.

Equipment 3/10

Scrubbers.

Used in very specific applications, usually in the metal sector in polishing processes. They are characterized by passing the extracted material through a water curtain that captures the dust carried in the airflow. The collected dust is removed by means of a dredge system to the outside of the unit. They include a recirculation system and water level control.

Equipment 4/10

Centrifugal fans

We offer different families of centrifugal fans: APTR for high pressure and SPM for low pressure. Both families can operate in either positive or negative pressure, are the ideal complement to Filter Units and Filter Cells in Extraction and Filtration Systems, and in Pneumatic Conveying. Their design and construction provide high reliability and low maintenance costs, and allow their use with materials capable of forming ATEX atmospheres.

Equipment 5/10

Cyclones.

Used mainly as a pre-separator or settling unit, they reduce the amount of extracted material reaching the Filter Units, prevent silo pressurization, and enable discharge from Pneumatic Conveying systems. Manufacturing them in anti-abrasion materials allows us to use them in a variety of installations handling highly abrasive materials.

Equipment 7/10

Ducting and accessories.

Our experience manufacturing our own ducting and accessories—using a variety of materials (galvanized sheet metal, carbon steel, stainless steel and wear-resistant steel)—enables us to provide extraction and conveying solutions for a wide range of materials, such as wood and its various derivatives, organic materials, paper, plastics, different types of metals, fiberglass, etc.

Equipment 6/10

Rotary valves.

They allow the transfer of material between different areas of an installation. Manufactured with cast or fabricated housings, rotors with rubber or metal blades, and mechanical adjustment with adjustable knives. They can be used in both high-pressure pneumatic conveying (up to 1 bar) and low-pressure systems.

Equipment 8/10

Storage silos and extractors.

We design and manufacture circular and rectangular silos for storing a wide variety of solids. Their construction is geared towards customizing the proposed solution, so we adapt storage capacity to each customer’s specific needs.

Equipment 9/10

Chain conveyors.

Used for moving granular solids, they allow conveying between different areas and at different heights. We have developed a complete range of chain conveyors, with versions ranging from a central drag chain and compact casing for small-scale production, to large units with dual chains and casings sized for high-capacity production.

Equipment 10/10

Screw conveyors.

They are volumetric conveyors used for transporting granular solids. Due to their design and construction, they are robust, highly reliable units with low maintenance requirements. Manufactured in a wide range of diameters—with standard, progressive or conical pitch executions, twin-screw assemblies, feed hoppers and fill-level control, etc.—these conveyors allow broad adaptation to the requirements of each project.