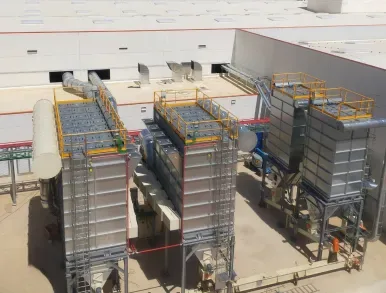

Extraction and filtration systems.

They are one of the benchmark solutions that OÑAZ offers its customers across a wide variety of sectors and applications—from extracting dust generated in countless production processes, to filtering flue gases from biomass boilers, as well as wet filtration using scrubbers for metallic dust.

Formed by the combination of:

- Filter Units that we select for each specific project from the wide variety manufactured by Oñaz. Mainly used for medium and large extraction requirements in centralized extraction installations.

- Filter Cells for projects with localized extraction and low airflows.

- Centrifugal fans which, operating in both positive and negative pressure, are adjusted to the specific airflow and pressure requirements.

- Cyclones when pre-separation of the conveyed material is required prior to the Filter Unit or Filter Cell to prevent saturation.

- A ducting network designed and optimized to reduce system pressure loss and prevent deposits of conveyed dust.

- Rotary valves that allow dust discharge from cyclones, filter units or filter cells.

Extraction and filtration systems can be complemented with other solutions such as Storage Systems, pneumatic conveying, etc., enabling us to provide end-to-end solutions to our customers.

Depending on the characterization of the extracted dust and its ability to generate explosive atmospheres (ATEX), the necessary protection and prevention elements are incorporated into the extraction and filtration system to provide systems that are safe, compliant, reliable and with a long service life.

Sectors

Woodworking industry

Biomass

Recovery and recycling

Galvanizing

Metal

Food and animal feed

Cement industry

Glass / Fiberglass / Rock wool

Varnishes and paints

Other